Resources / Learn / Customer Stories / Finland

Fast, accurate stockpile inventory helps Rudus plan production and reduce costs

Rudus is a leading manufacturer of stone-based building materials based in Finland. They pride themselves on serving as a one-stop shop for builders as a source of concrete, concrete products, aggregates, and recyclables. Project Engineer Ville Venäläinen has worked at Rudus for five years in both sales and production roles. As a self-proclaimed enthusiast of big cars and big machines, Ville loves his job—especially now that he is helping to digitize Rudus’s processes. As part of his day-to-day work, Ville completes drone surveys using Propeller and teaches others on the team how to do the same. Read on to learn how Rudus uses Propeller to plan production, understand their costs, and ultimately save remarkable amounts each year.

The challenge: planning production and understanding costs

When he was still a student writing his thesis on aggregate production, Ville found himself thinking deeply about how to document production for improved planning. When he and the team heard that other CRH operating companies were using drones to survey their worksites, Rudus started to explore how they might use similar technology to help them plan more effectively.

Communication was also a challenge; describing on-site conditions using words alone can easily lead to misunderstandings. So Ville and about five other team members often found themselves traveling to a site to see one very simple—but very important—thing. All the travel took up a lot of time that could have been spent solving problems rather than understanding them.

Before they found Propeller, Rudus used an outsourced surveying solution that did little to improve matters. The surveys weren’t downloadable and couldn’t provide many calculations, yielding no insight into stockpile volumes. The data they did provide took days to come back, which was simply too slow on an active job site.

The solution: fast, easy access to site calculations

According to Ville, the top benefit of using Propeller has been speed. “We need site data now, not in two weeks,” he told us. “Propeller is easy, fast, and accessible.”

While describing on-site conditions in words is nearly impossible, Propeller has helped Rudus develop a shared visual understanding of what’s happening on the ground. With a 3D map, measurement toolbox, and reporting dashboard all in one, production managers and others have easy access to point-and-click measurements, improving communication and reducing the need for site visits.

“Also, it’s quite exciting to do drone surveys. I like it—it’s fun,” Ville added with a smile.

Documenting and planning production

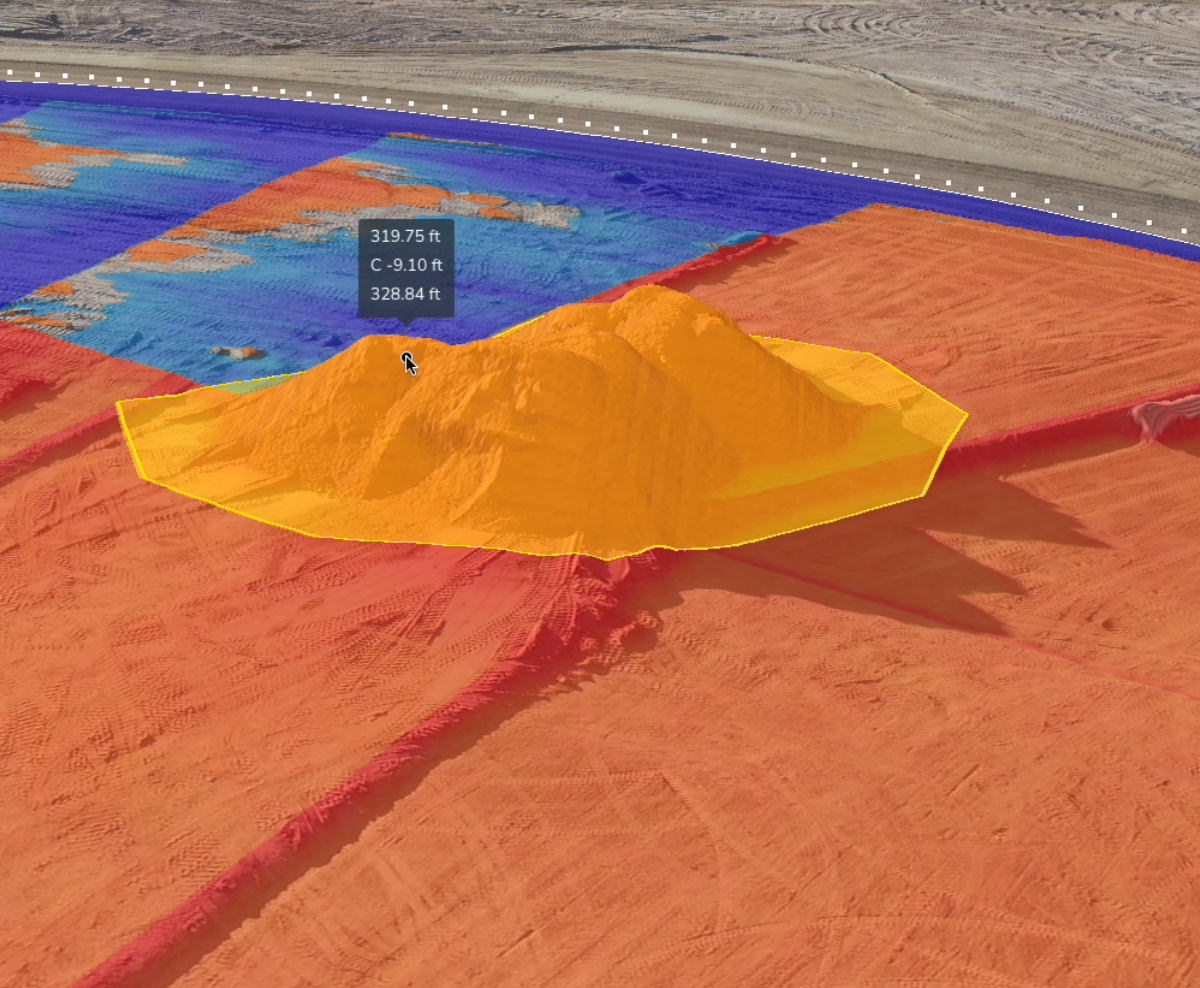

Today, Rudus uses Propeller to calculate production volumes, like how much blasting has been completed and how much is left to go. Regular drone flights make checking cut-fill and stockpile volumes quick and easy, with downloadable data that can be distributed and shared with everyone who needs it.

“We use Propeller as an updated map at the site to see what the situation is and to make plans for future production,” Ville said. These checks can be done without physical site visits—a significant efficiency gain.

Propeller has impacted production at every level, down to the very smallest rocks. The mining team uses the platform to estimate their level of effort when hammering down stockpiles of too-large rocks into a smaller size. Hammering rock is labor-intensive and expensive, so calculating the cost of this work is invaluable.

Calculating and predicting costs

For Rudus, soil stripping has long been one of the most significant project costs—but it was also very difficult to estimate. Without a clear understanding of how much earth was being moved, costs from previous projects were the best way to create estimates for future work.

Using Propeller, Ville and his team can compare two surveys to see how much soil has been moved. By understanding the volume of earth they’re moving, they can use their actual costs to calculate the cost per cubic meter, helping them plan and forecast more efficiently for future projects.

“We hadn’t gone through this data before because it wasn’t available, but now we have the information we need to understand our costs and plan accordingly,” said Ville.

Thanks to this improved understanding, Rudus is reworking their contracts to pay a predictable fixed cost by volume of soil instead of paying by time—an unknown figure that can fluctuate significantly. Contractors can bid based on the volume of soil they need to move, and Rudus gets a handle on the total cost before work begins.

Accurate inventory and production tracking = cost savings

When we asked Ville if he could put a number to the value Propeller has provided, he shared the spreadsheet he uses to track ROI. Keeping an accurate stockpile inventory has been the biggest source of cost savings for Rudus. Including drive time and other labor hours saved, they’re already saving a huge amount of costs per year.

“We also expect to see production savings, which will improve our return on investment even further,” Ville said.

“If we used Propeller perfectly across all our sites and plans, I think it would save us about a six-figure number of euros per year. That’s just a rough calculation, but the numbers really do add up.”

Instant on-site elevation checks

One benefit that took Ville by surprise was the value of Propeller’s mobile app. “We use the app on-site to check the elevation of the place where we’re standing,” he told us.

Rudus once spent ~€200 per measurement to have a surveyor manually capture these data points—which took days to come back—or they relied on fixed elevation points that were never quite in the right spot. Now, they can open the app and get an instant answer.

The app also makes it easy to show contractors, clients, environmental officials, and other stakeholders about a feature or a situation on-site. Everyone always has their mobile device handy, so they don’t need to carry a computer to share an easily accessible view of ongoing work.

“We can even take a photo at the site and upload it straight to the map in Propeller. The team figured out themselves that they could do that with no training; it’s self-explanatory and so user-friendly.”

One map, one team

Several teams within Rudus are using Propeller, from the Production Managers to mining and crushing crews to environmental staff.

On-site teams ensure they’re working within environmental regulations by tracking where they’re digging compared to enforced worksite perimeters. When officials make unannounced site visits, Propeller makes it quick and easy to demonstrate where work is happening compared to approved designs.

Ville also sees value in Propeller as a recruitment tool. At a time when much of the industry’s workforce is nearing retirement age, with insufficient numbers of next-generation workers applying to take their place, firms like Rudus face a potentially serious labor shortage.

But, Ville says, Propeller and other technology tools help pique the interest of workers keen on boosting their technical skillset. “Every time I fly, someone comes up to me and asks me questions about what I’m doing and how it works,” he said. “Our list of users is growing all the time.”

Want to know how Propeller can help you?

Learn more about Propeller’s products, pricing, and how to get started on your site.