At family-owned and -run Blount Contracting Inc., saving even an hour in somebody’s day makes a big impact. After struggling to process high-volume survey data on their own, Blount looked into using Trimble Stratus, powered by Propeller.

Trimble, the global leader in positioning technologies, was an early partner of Propeller. Our teams work closely together to deliver Trimble Stratus survey-grade drone data solutions for the heavy civil industries.

Based in Arizona and started in 2000, Blount Contracting is a heavy civil construction services contractor with a national reach and Trimble Stratus customer. Their projects include a renewable portfolio with solar, wind, and hydroelectric projects. Additionally, they perform industrial and commercial projects focusing on earthwork, mass excavation, deep foundations, and earth-retention.

Superintendent Nick Blount spearheaded the adoption of Trimble Stratus to process and visualize worksite survey data while he served as GPS manager. In this previous role, he had managed all the drones and modeling for the company.

Self-processing data was too time-intensive for their workload

Though based in Apache Junction, Arizona, Blount Contracting has projects as far east as Mississippi. This geographic array of projects means they need to be able to do processing from multiple locations—for many different jobs.

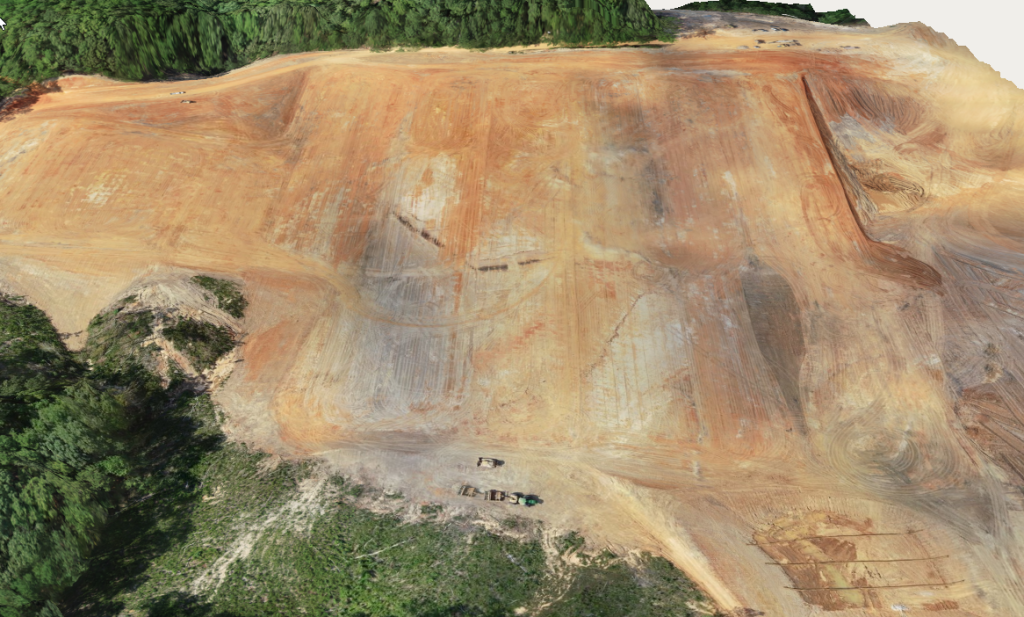

“A large solar job can be 300–1500 acres,” explained Blount. “You can look at our Mississippi job. We basically load one to two flights Monday through Friday, sometimes Saturday. We have a lot of volume moving each day that we want to keep track of.”

In the past, Blount had to tie up a specialist and computer to process drone flights and everything else. It was a big drain on resources.

“We were on Pix4D,” explained Blount. “We don’t use it anymore. We’ll pay more for Trimble Stratus over time, but if you consider the money spent paying someone’s salary [to do processing] it’s less expensive, plus you free up that human capital.”

It was also difficult to plan out the day for processing. “If you had a laptop, you couldn’t do anything else on that machine,” said Blount. “I’d have to plan my day so I started processing at the end. Otherwise that day would be unproductive since the bulk of the computer’s resources would be tied up processing.”

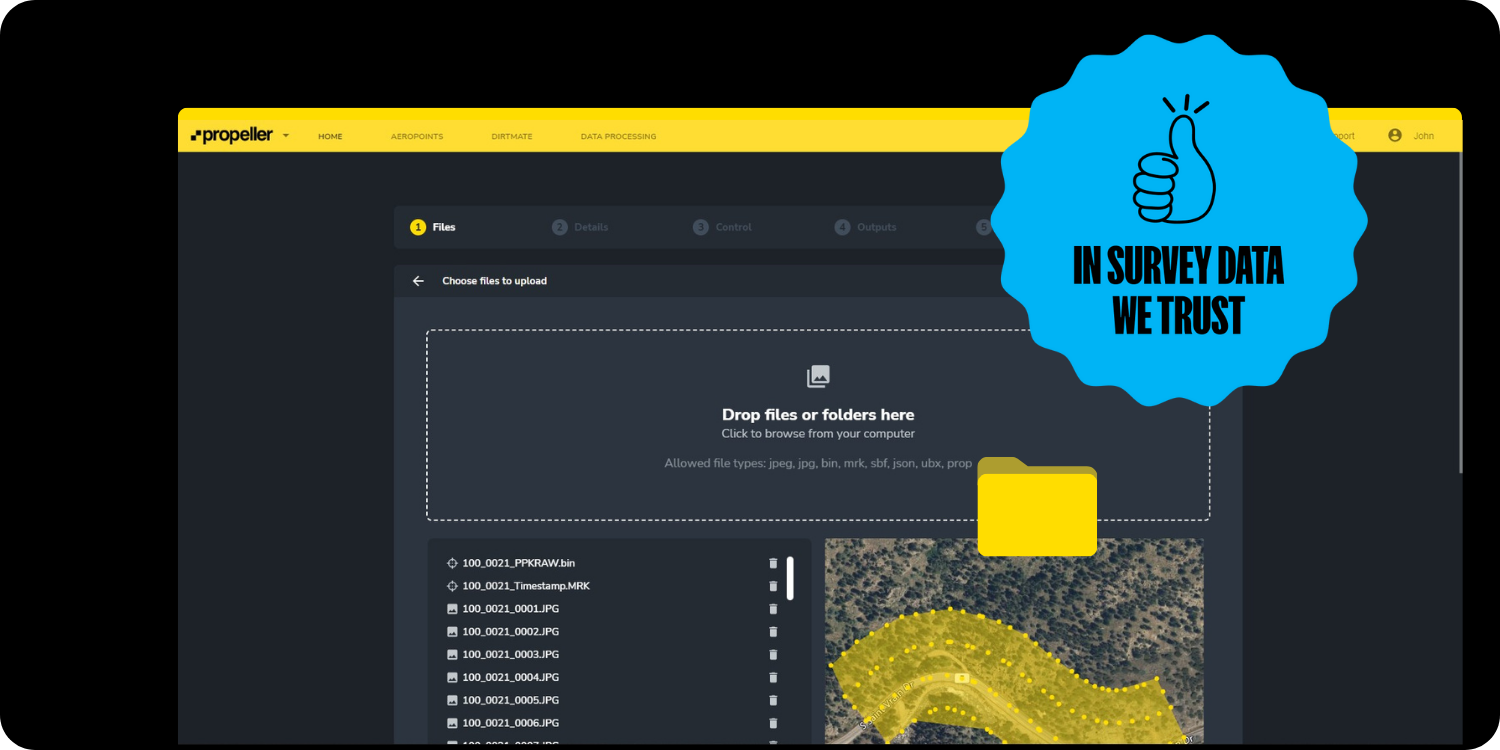

The switch to a cloud-based platform like Trimble Stratus was worth it for processing power alone. But more than that, Blount Contracting is now able to upload from wherever they are, work on multiple surveys simultaneously, and work on huge projects without worrying about processing workload.

“I can basically have whoever has a Part 107 fly and upload,” said Blount. “Notoriously, I’d be the one doing it all. But the Phantom 4 RTK is very user-friendly, so with a three-hour training, they’re up to par and can run the actual drone.”

Using Trimble Stratus, Blount puts full days back on the clock

As a company that values technological innovation, Blount Contracting has been flying drones in their operations for more than five years.

“They’re one of these guys who are super innovative—and if it’s an accurate, faster solution, they are willing to do it,” said Ridge Nielsen of SITECH Southwest, who has worked with Blount Contracting for years.

“We’ve always used RTK drones,” recalled Blount. “The change was with AeroPoints and post-processing. We set up permanent ground control points on many of our jobs—probably saving a good three hours on a big job by being able to set the AeroPoint down on known points.”

When asked about the advantages of using the Propeller PPK workflow, Blount said he “only has to put six [AeroPoints] down for a job I’d normally have to have 18–24 on.”

This is a major reduction in ground control setup time, which every drone surveyor knows can be exhaustive. “Despite the reduction in the number of control points, we have continued to see very accurate data produced on a very consistent basis.”

Going beyond site surveys

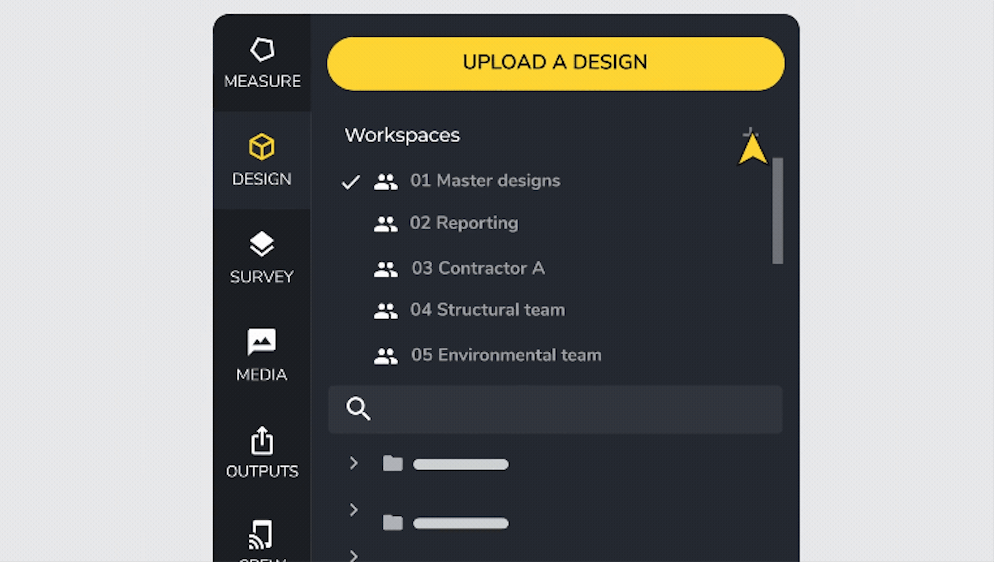

At first, Blount’s team used Trimble Stratus for many standard workflows, like daily and weekly quantity tracking. “But we realized there might be powers people are underutilizing,” said Blount. “We’ve learned that there’s way more than just ‘we’ve moved 2,000 yards’ or ‘it can do an as-built’.”

That’s where balance regions come in.

“We took the capabilities of how [Trimble Stratus] lets us create polygons for boundaries and see what the cut/fill is. We topo an area and figure out what it’s going to take to balance some specific area and then can create linework that is sent to the field to ensure everyone moves the soil in the most efficient way possible,” said Blount.

“I’ll do that for, say, dozers and we’ll create 20 dozer push areas. I’ll take those outlines and export from Trimble Stratus and into Trimble Business Center, then I can make my surfaces based on it.” It takes just a couple of hours and Blount can then tell their operators to work in a specific site area, e.g., push area 1A. The operator turns on push area 1A in the cab and there’s one surface to work from.

“I know it balances because we’ve looked at the numbers,” said Blount. “All of our guys in the field say ‘I don’t know how you guys make these now, but we need these on every big job.’”

Creating balance regions traditionally would have taken a couple of days. “I could never see cut/fills and know my region at the exact same time,” he recalled. “With Trimble Stratus, I can virtualize it in 30 seconds. I couldn’t tell you how many hours I’ve saved because of it.”

Using 3D maps and measurements to settle disputes

There’s more to Trimble Stratus than making work easier on site. It can also help in meeting rooms and to settle internal and external disputes.

One of the simplest tools Blount used in these situations is the cross-section comparison. “We can show them problems in their designs by pulling up the cross-sectional view,” said Blount. “Instead of printing something, you can actually show them, ‘this is what your site looks like’ and ‘this is what it did look like’ and ‘this is where we’re at’.”

“We had high expectations for Trimble Stratus, and it met those expectations.”

Blount Contracting has been using Trimble Stratus and the Propeller PPK solution for a year. In that time, they’ve been able to use the platform for vital quantity tracking and as-builts, but also much more, like balance regions and machine surfaces.

And all of that accurate, accessible data means Blount Contracting has seen cost-savings at a high level.

“You can see something’s going wrong [on site] and identify it because you’re able to quickly return the data,” Blount emphasized. “We had high expectations for Trimble Stratus, and it met those expectations.”

Blount Contracting uses Trimble Stratus powered by Propeller.