We’re documenting DirtMate’s beta journey with episodic updates on its development. This series is your window into the product roadmap—the source of truth for progress reports and beta user stories.

In Episode One, our host, Richard Hordern-Gibbings, leads an open discussion with Propeller CEO, Rory San Miguel, and Angus Keating, DirtMate Product Manager, to dig into how DirtMate works and where we go from here.

If you’d rather listen to the discussion, you can do that by playing the recording above.

What is DirtMate?

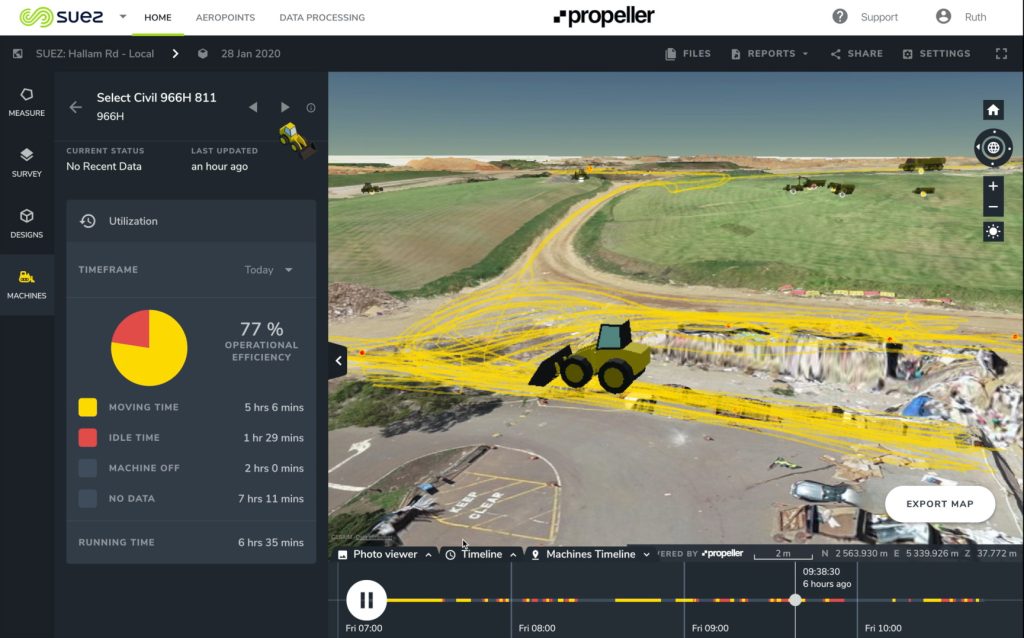

DirtMate is an easy-to-install, cost-effective machine tracking system that gets you up-to-date volumes every hour, from any device. DirtMate sensors get mounted onto your active machines, and the sensors collect earthwork progress data in real-time.

That data powers 3D surfaces that you’ll use to generate cut and fill heatmaps, utilization graphs, and progress-to-design measurements. For the first time ever, you’ll know exactly what headway you’re making, where it’s being made, and when.

Rory: Propeller for the entirety of its life has processed customer drone surveys in big 3D maps, and our tool gives you the ability to track changes on the worksite over time. It’s really around earthmoving.

What we noticed is that people were going from quarterly to monthly, monthly to fortnightly, and fortnightly to weekly drone flights as they started doing it more.

It’s this cycle, but at some point they stop increasing their usage, and to be honest, we don’t see people flying more than a couple times a week. Now, what we’ve heard is that customers want daily data, so there’s this desire for daily data and this impasse where people aren’t flying as often as they want to.

We went back to the drawing board almost two years ago now, and thought about how we’d solve the daily data problem if we were starting from scratch today. The idea initially was to get the AeroPoint, which is a really accurate GPS sensor, and stick it on the back of every machine—figure out the height to the ground and as the machines are moving on site, we get GPS positions. Essentially, we’re able to get elevations in real time and turn each earthmoving machine into a survey rover.

So that’s really where the concept of DirtMate came from. We’re 18 months into the build, we’ve got new hardware. It’s solar-powered with long-range wifi connectivity and RTK GPS, and all of those positions stream back into our servers where we do the post-processing and mesh the elevation with the drone surveys to get real-time quantities out of that solution.

How does it work from a technical standpoint?

DirtMate is magnetic and solar-powered, which supports a quick, 10-minute installation.

Built-in survey-grade GPS receiver collects elevation data from the ground underneath the machine in real time, while an IMU tracks machine vibration to determine utilization metrics (idle, working, off).

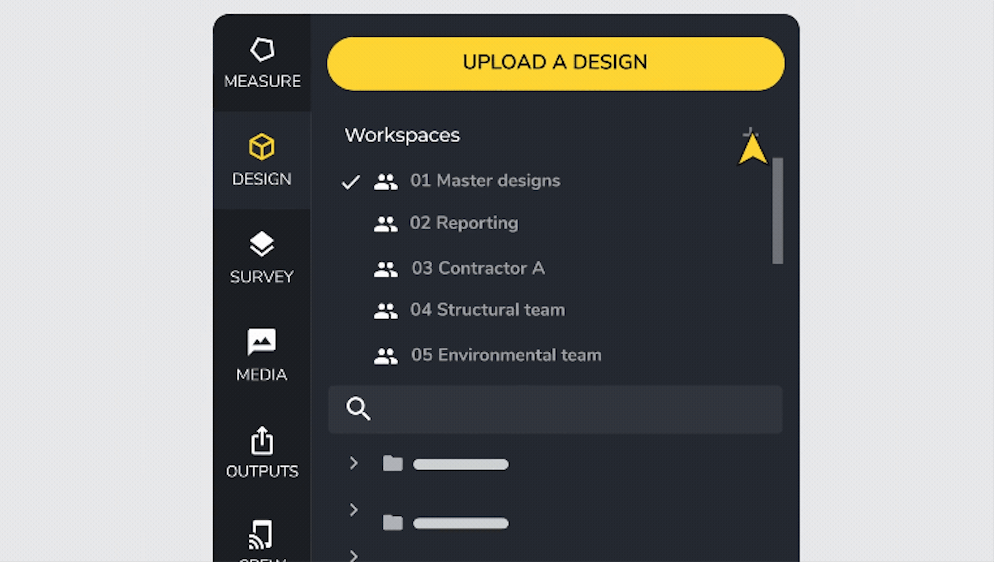

All that data feeds back into the Propeller Platform to update the 3D surfaces from your last survey.

Angus: Each DirtMate is, as Rory said, a GPS rover. The idea is that each of these guys have a RTK GPS unit that records all of its data and sends it back to our surveys. Using that GPS position, alongside a measure-up of the machine, we can work out where the ground is.

Different from other machine control systems, we don’t track the blade, we track where the wheels have been. Using that, we can work out where and when any dirt on site was moved.

What makes DirtMate a unique product? What are its differentiators?

These are DirtMate’s differentiators:

Easy install: Magnetic, solar-powered design

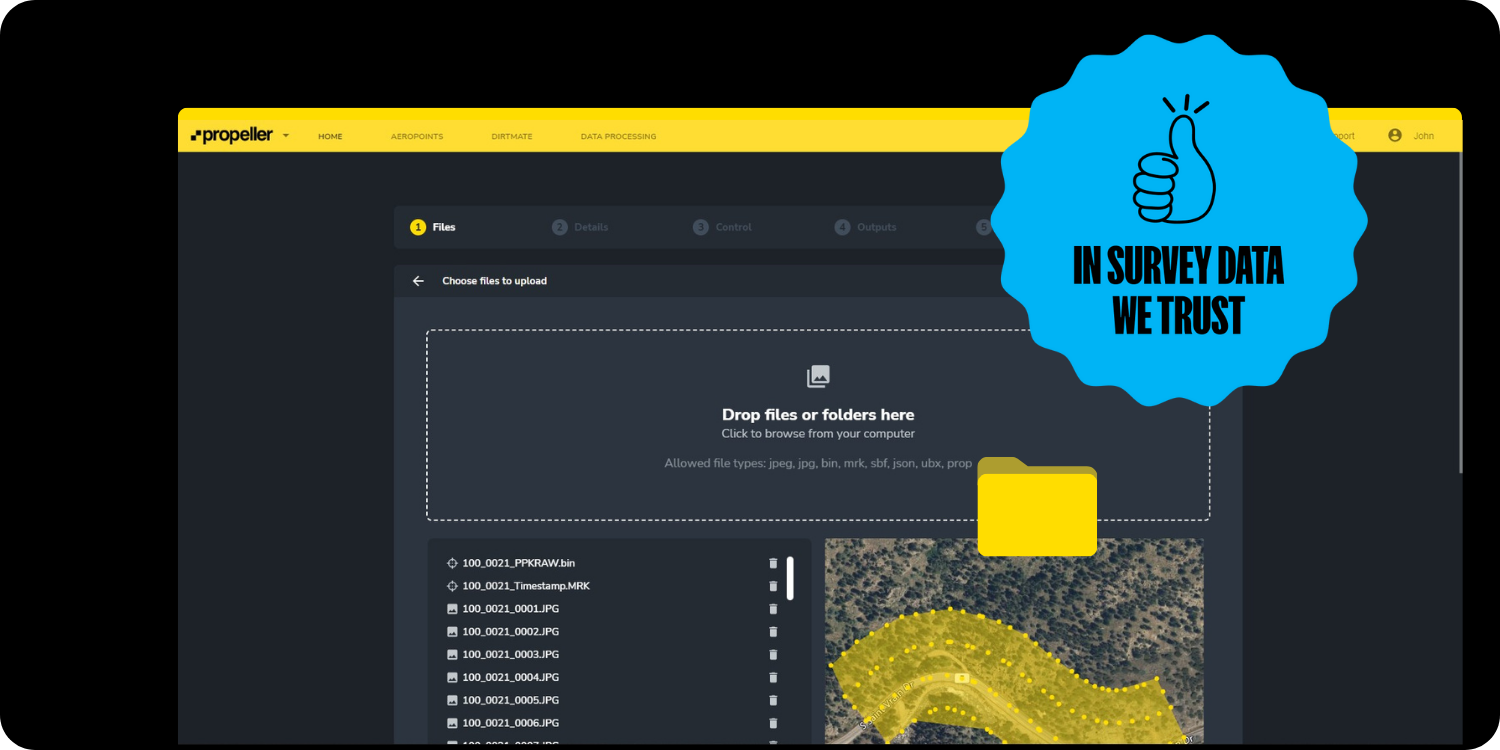

Data confidence: Layer machine data over drone surveys to verify accuracy

Price point: Inexpensive and available to all machines

Real-time volumes: Translate machine activity to volumes in real time

On-board IMU: Accelerometer to detect angle and vibration

Angus: We wanted it to be easy to install with this magnetic, solar-powered setup. A lot of sites have subcontractors coming on and coming off their sites, and we want to make sure that no machine is missed. Once you have full-fleet coverage, you’re not missing any data or dirt that’s moved on your site. Being easy to install is one of the critical components of this technology.

At Propeller, we’re all about confidence in data. We want this product to follow our drone survey legacy, and we want people to be confident in the data they’re getting back. That’s one problem we’ve seen with existing technology—when you can’t verify your data, it’s difficult to have confidence in it.

What makes DirtMate unique is that we’re layering all that machine data over the last drone survey. That makes it really easy to double-check accuracy and verify the numbers you’re getting from your machines.

From my perspective, those are the two things that make this really unique.

Rory: I’d probably add that we’re targeting DirtMate to be a relatively inexpensive solution, and that’s important because for the first time, we think it will be feasible to kit up every piece of machinery you have on site. This could also include non-machinery, down to the foreman’s pickup track.

What’s interesting about us heading in this direction—us making it inexpensive and available to all machines—is that once you have every machine covered, there’s a much smaller chance that the site in real life and the site in Propeller become out of sync. We have a higher chance of being able to report accurate and verifiable quantities.

There’s another benefit there, as well. Each DirtMate has an IMU, an accelerometer to detect angle and vibration. If we imagine a haul road out on site, it’s not changing as much as the areas of cut and fill. If we have 10 machines going across that haul road (or 100 machines) every day, and we’re checking the elevation each time, we can actually detect errors in the calibration of the machines automatically and much more robustly than before. There’s almost a strength in numbers aspect to DirtMate.

Angus: Also, it ties machine activity information directly into the volume information. There’s a lot of guesswork around estimating volumes from truck counts, and now we have a way to validate those numbers. There is value in measuring truck counts, but being able to have all your machine information and all of your volumetrics in one platform, gives you an awesome opportunity to tile that information together.

Would you say the beta announcement was a success? What kind of feedback did we get at ConExpo?

ConExpo was a success! Overall, the response to our DirtMate announcement was very positive. We were able to source beta program applicants and collect some really great feedback from the people that would be out there using them everyday.

Rory: It was a big success. We wanted to see how this idea stood up in the public eye, and generally speaking, I think it stood up really well.

We had a bunch of Propeller people out there and we had a booth. All week we had people stopping in to ask about DirtMate. And one of the most promising things to me is that the concept quickly made sense to a lot of people.

They understood how it fit into our existing solutions. So it was a success from that perspective. In terms of getting people to sign up for the beta program, I know there is a fair bit of work to actually developing the solution.

The three focus areas are: reliability of the data coming through, accuracy, and then, usefulness. We’re working on those three areas actively.

What does the beta journey actually look like? How are we selecting participants?

We’re looking for beta users from each of our four industries: construction, mining, aggregates, and waste management.

It’s going to be an iterative process—we want every user to feel like they are receiving some kind of critical usefulness from their DirtMates on site.

Angus: As far as the customer pool, we really want people from each key vertical. We want to work with some mines, landfills, quarries, and civil construction companies because we want to make sure that we’re building the right thing for the right people.

Rory: Look, if you have lots of machines on site, moving lots of material, we want to talk to you. And at all times, we want to be delivering some kind of critical usefulness to the customers that we’re already working with. It’s a bit of an iterative process.

We’re already working with a few accounts now: one landfill and two construction companies.

What does the glorious future of DirtMate look like?

Getting live volumes, getting utilization data, getting insights in front of the people who need it—that’s really where we’re heading with this.

Also, having the technology become this watchful eye over your site. If you’re breaching design or digging outside of boundaries, we want to be able to set up ways to automatically track those thresholds and get alerted when something happens.

Rory: We’re committed to helping our customers track, and ultimately improve, their progress and productivity on the worksite. It’s no secret that projects often run over time and over budget, and we think that’s potentially because of how hard it is to track progress against targets.

What we’re trying to do is build solutions that close the loop on what’s happening on site. To us, drone surveys are just one data feed, and DirtMate is a crucial secondary feed. As Angus mentioned, it’s not just about the final surface, it’s about understanding how you got there.

For us, what we’re trying to do for our customers is figure out the right combination of fleet, working for this long, in these conditions, equals this much progress. Over time, we expect to be able to combine all these survey sources together into one big consolidated model, and make it really easy to use whether it’s in the field, on the phone, or in the office.

Getting live volumes, getting utilization data, getting insights in front of the people who need it—that’s really where we’re heading with this. Also, having the technology become this watchful eye over your site. If you’re breaching design or digging outside of boundaries, we want to be able to set up ways to automatically track those thresholds and get alerted when something happens.

Instead of having to pour all over a map everyday, we want to start telling the computer how to look for these things and send you a report. That’s really where we’re heading with this.

Easy, affordable, comprehensive tracking and improvement for the worksite.

What has the development team been focusing on?

The three main things we’re focusing on are reliability, accuracy, and usability.

Angus: The three main things we’re focusing on are reliability, accuracy, and usability. At the moment, we’ve realized that trying to roll out to lots of sites before you have solid reliability complicates things.

What we’re focusing on right now is figuring out what we can build, what we automate, and how we can get this product to the point where it can scale. When something goes wrong on your site, we need to notify you what went down and that we need to fix it. And we also need to make our system more robust so things don’t go down in the first place. There are a whole lot of things we can do there to make this product easier for our customers to use and our own teams to support.

The next focus area is accuracy. Right now, we’re getting a whole bunch of data into the platform, but we don’t have anything in place that makes it really easy for the customer to cross-check the data and validate accuracy. For example, just having the ability to import check points along a haul road to make sure that all of the trucks that drive past are accurate there. There are a handful of things like that, which makes verifying accuracy easier.

And lastly, the usefulness of the product. As we talk more and more to the customers we’re working with, they’re able to give us more feedback. We’re honing in on that feedback. While there are a few different personas on site who will use DirtMate differently, getting more information to the supervisor or foreman on site is one of the key pieces of value we’re hoping to provide with this product.

If I’m watching this right now and I’m interested in being part of these beta trials, how do I get involved?

Get onto www.dirtmate.com and apply for our beta program!

Rory: Get onto www.dirtmate.com. There are two buttons: “Register your interest” and “Apply to join the DirtMate Beta Program.” Sign up for one of those lists.

We’d love to hear as many details as possible about the projects you’re working on.