Shawn Swygman is the GPS manager at Elder Corporation, one of the largest contractors operating out of Iowa, with over 250 employees and 100 active sites. Shawn is one of a growing number of forward-thinking individuals in civil construction whose job revolves around seeking out and integrating the newest technology into their business’s operations, allowing everyone to do their work faster and more efficiently.

As the one leading the charge on new tech, Shawn’s made himself an expert on everything from machine control to GIS to 3D modeling, and, most recently, drone surveying.

After a bumpy start with one of our competitors, Shawn found Propeller and has fully integrated drone surveying into his company’s technology portfolio. Recently, he sat down with our CEO and co-founder, Rory San Miguel, to talk about what led him to Propeller and how it’s changed the way he gathers and shares survey data.

You can check out their conversation in the video below or read on for a quick summary of what they discussed.

Shawn’s flightpath to Propeller

Before committing to Propeller, Shawn spent a year using Pix4D, but was never able to fully integrate it into his workflow. And because of this, he ended up flying his sites only a dozen times in a single year.

“There’s not a whole lot of training going on with [Pix4D], so I basically had to learn a lot of it on my own.”

In addition to the thorough training we provide pre-flight, Shawn sees a lot of value in our remote support teams.

“I have a question, within ten minutes I have an answer and I’m moving again. I’m very grateful for the support staff. I tell them all the time they’re the best support staff I’ve ever worked with.

“I used to dread going out and flying the drone. But going out with the Phantom 4 and creating a .KML in my office, taking that out already loaded, flying my site, and then using the AeroPoints is the way to go. I look forward to going out and flying the site no matter where it is or how big it is.

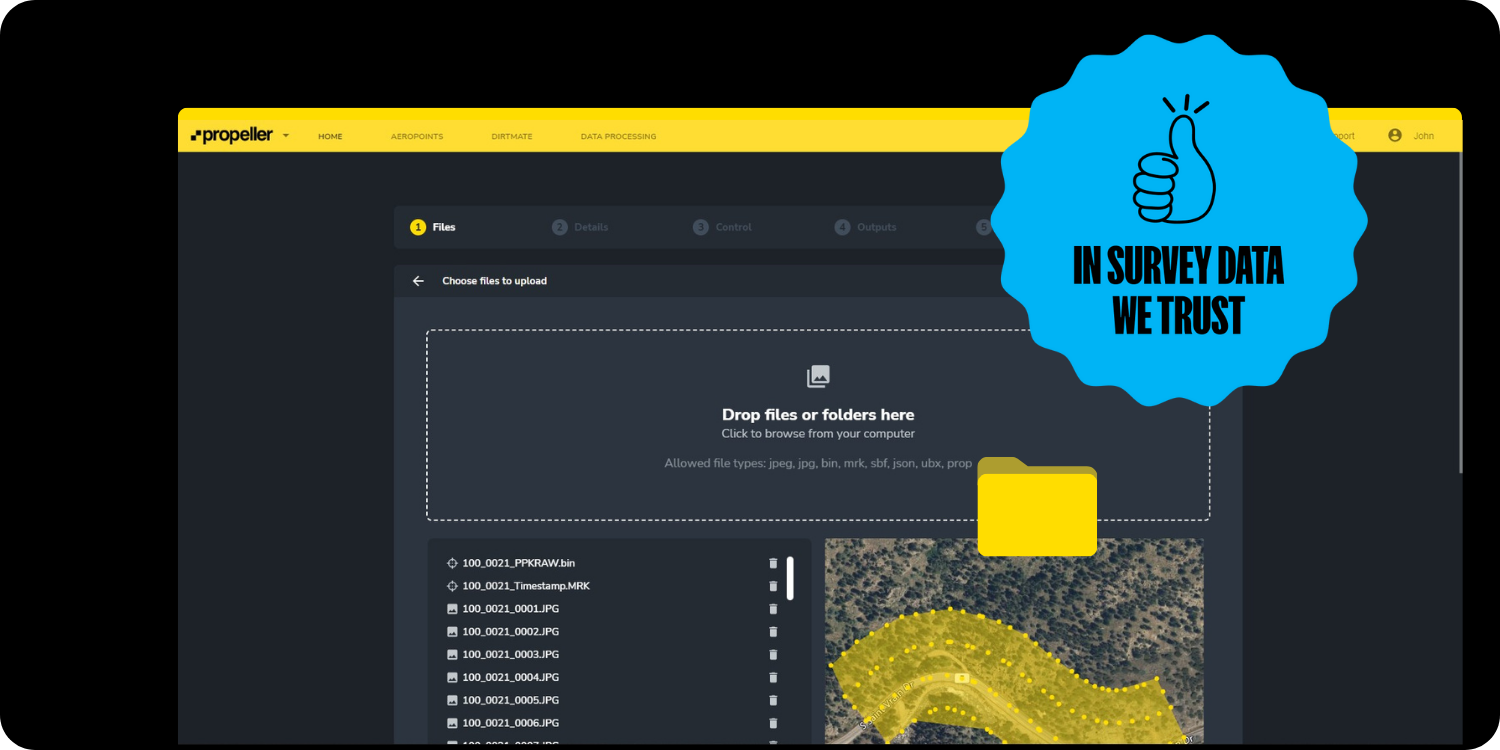

“Propeller takes you through step-by-step and then it’s done. You get your data back already processed, you don’t have to do anything. It’s complete. Then you just have to run your areas of cut/fill, and quantify your stockpiles.”

Shawn says among the things that impressed him when he began demo-ing with Propeller’s sales team, something that really stood out to him was the AeroPoints, our smart ground control point solution.

“I’m curious by nature, and when I first saw them I wanted to know how they worked and how they could benefit me. It’s really cool how I can pick up all my AeroPoints, throw them in the back of my truck, and hook up my hotspot and just watch them all upload. By the time I drive back here, they’re uploaded. I can go site to site to site and set them up and the people from Propeller take care of me.”

How smarter ground control and offloading drone data processing gave Shawn more freedom to scale

Pre-Propeller, Shawn’s drone surveying workflow was overly complicated and took up valuable time he wanted to be using on his duties, like programming machine control models. Here’s how he explains surveying with Pix4D:

“I had to go out on site, set up my ground control points, and take my rover with me. Then I’d have to start the program and set the flight path, and I’d have to do all that stuff in my computer while I’m on site. Then I’d fly the site, then go around and shoot ground control points. Once I was done with that, I come back, run another program, load up the log files and the pictures, open up the software, and then go through each image, making sure I’m processing them the right way.

“Processing the data is a huge part of it. For me, to take time to go through all the pictures, and try to find my ground control points…it just took forever. I’m just sitting there, watching my computer run while I’m trying to get other work done. It just became kind of a hassle. It was a process and now [with Propeller] my work is limited.”

Now that he’s cut self-processing out of his job scope and found a more intuitive drone surveying workflow, he’s able to delegate some of the flights to others and accomplish other tasks.

“I build the machine models, and I also build utility models. I just hired another guy who’s coming in, and one of his big tasks is to fly the drone. That way I can focus on all the modeling I have to do.”

On helping his team self-service and keeping Elder Corp ahead of the curve

By supplying his project managers and stakeholders with more accessible, more frequent survey data, he’s given them the power to check site progress themselves and plan operations more easily.

“We can do it the old school way, or I can fly a site once a week, share the data with the project manager, and then he can go in there and look at his cut/fill areas and see how much dirt he has that needs to go from section A to section B.

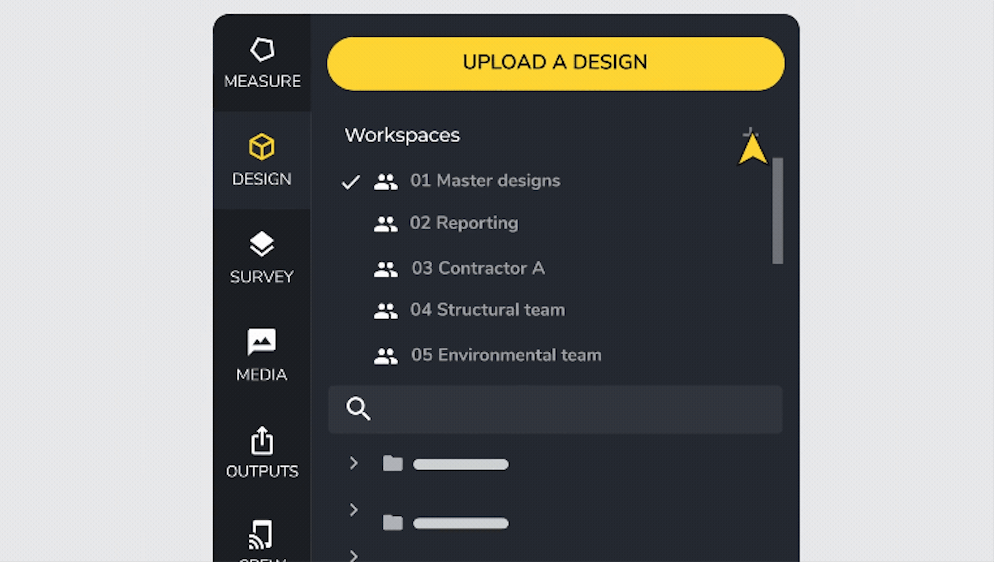

“[Propeller’s] made it easy for me by allowing me to share everything from my laptop, share anything with those guys. Even the foremen and superintendents, I can invite them into the platform and they can just log on and see everything themselves. And customers that come into my office, I can show them this fantastic 3D model and they’re blown away.”

Shawn explains his mission seeking out new technology solutions pretty simply: “I want the best products, the best solutions, getting the best accuracy so we can get the job done fast and get the job done right.”

A big force in Shawn’s technology stack—not just at Elder Corp, but in his fifteen-year-long career in construction technology—has been Trimble. Shawn uses Trimble Business Center and, most recently, the Trimble Earthworks for Excavators Grade Control Platform.

By getting his company to invest in Propeller and Trimble solutions, Shawn believes he’s keeping Elder Corp ahead of less progressive competitors.

“I think as the technology grows, it will only get better and better. If you’re not keeping up with drone technology, you’re going to fall behind.”