Resources / Learn / Customer Stories / Georgia, USA

Plateau Excavation powered by Propeller: Boosting collaboration with 3D surveys

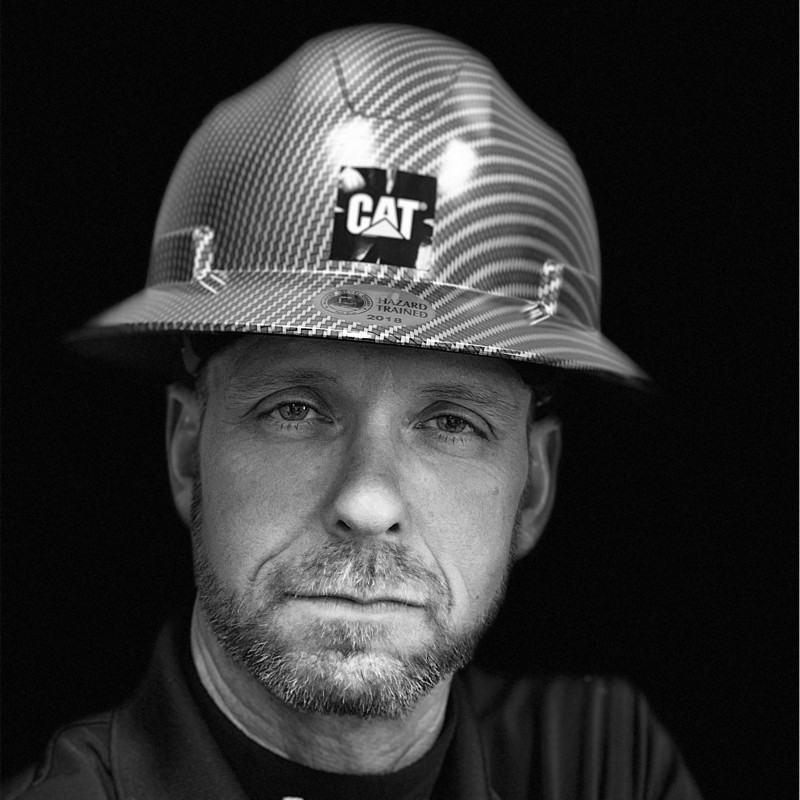

Plateau Excavation uses Trimble Stratus, powered by Propeller. Trimble the global leader in positioning technologies, was an early partner of Propeller. With SITECH South‘s drone division, SISO Air, we work to deliver Trimble Stratus’s survey-grade drone data capabilities to contractors of all sizes in the heavy civil industries. Specializing in industrial construction, Plateau Excavation is one of the largest site infrastructure contractors in the southeast United States. With over 40 years of experience, it’s safe to say Plateau knows a thing or two about sitework — and it shows. But Plateau is leading the change in more than just quality of work; they’re pioneering new ways of working powered by ongoing digital transformation. Plateau Excavation believes innovation will drive the future of infrastructure improvement, and they’re continually investing in new equipment and using technology to meet future challenges and grow. Paul Shepard has been with Plateau for a little over three years and works as their UAS (Unmanned Aircraft System) Specialist overseeing their drone survey operations. With his previous experience flying drones and using Trimble Stratus powered by Propeller, he helped Plateau use drone survey technology to obtain more accurate topographical maps of their worksites. Today, the survey teams fly the worksites every two weeks to ensure they have the most up-to-date data on the material being moved. “We like to monitor how the dirt is moving on site and make sure we can set the building pad elevation as accurately as possible to help us balance that site,” Paul explained. “Once the pad turnover date comes, we typically slow down to maybe a flight once a month or so, just to see how things are progressing. The drone workflow is so much easier than a ground topo, and our team likes to regularly review that updated orthophoto, even if we don’t pull any data from it. Even if you don’t think you need it today, it can prove helpful down the road.”

Boosting collaboration with 3D maps through site visualization

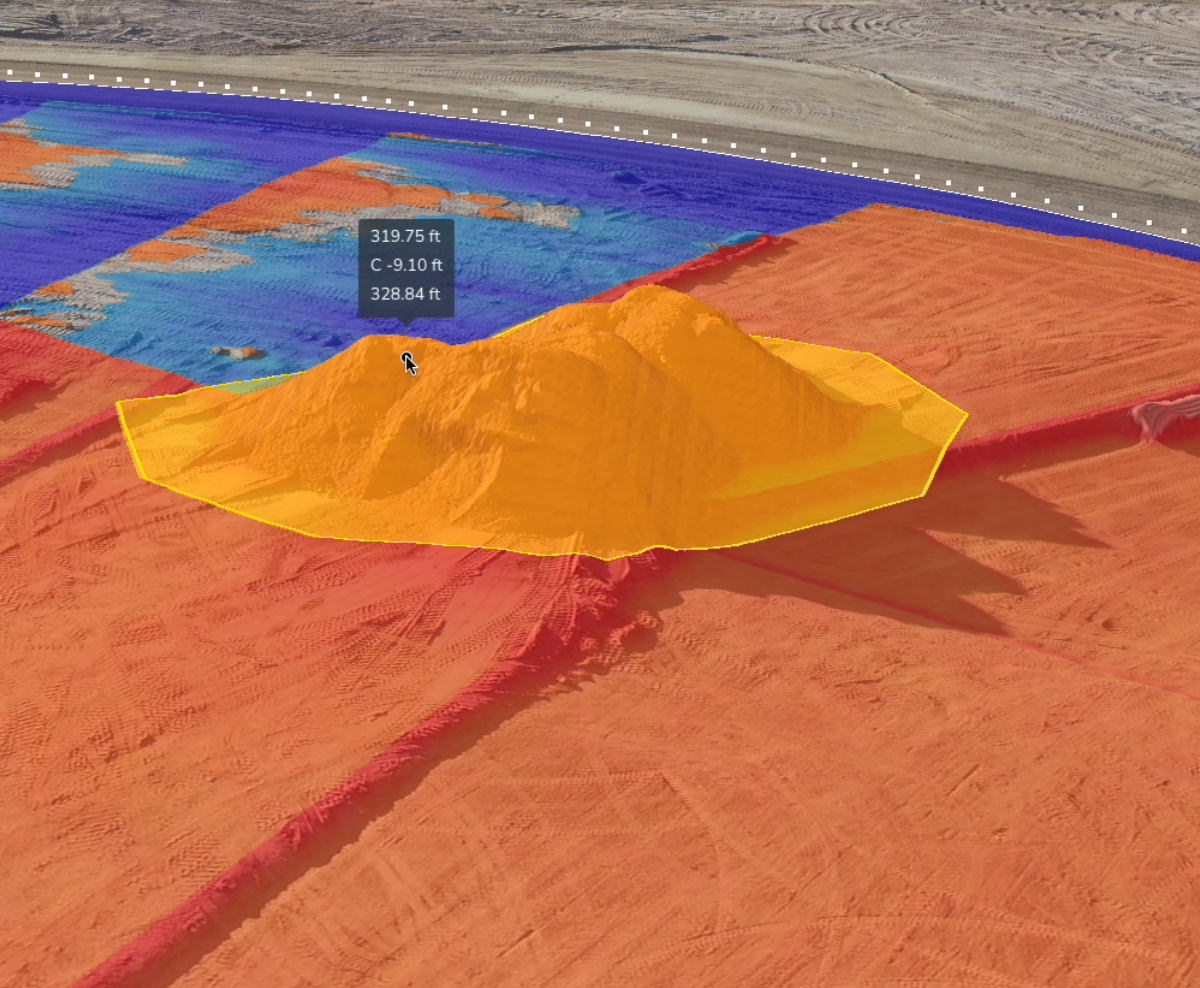

Hyundai is partnering with SK Battery to build a new battery plant in Bartow County, GA and Plateau Excavation is the general contractor. They have 200 pieces of equipment on this 600-acre site, moving 400,000 yards of dirt a week for a project total of more than 11 million cubic yards of dirt. To monitor progress, the site is flown once a week. Once they get their data back from Trimble Stratus, they’re able to monitor the material volumes that need to be moved. They can also export the data to other applications in their workflow, like Trimble Business Center, to ensure they have accurate data when they submit their pay apps to get compensated for the dirt they’ve moved each month.

Plateau’s project managers meet weekly to discuss progress on the Hyundai battery plant, as well as their other jobs using the latest site maps in Trimble Stratus for easy site visualization. Their field teams use Propeller’s mobile app when on the worksite to aid in their decision-making.

“We try not to let any of our sites have a flight older than one month so that the teams have the most recent photo,” Paul added. “And with the app our guys in the field are able to zoom in very clearly on specific areas of the site with their iPads to check progress and make measurements. It’s a great tool.”

Using survey data to help design and spot errors

Initially, when Paul brought Trimble Stratus to Plateau, there was some skepticism around how accurate the data was. But now, the data is so trusted that some project managers are using the tools to create designs.

“We’ve got a couple of project managers that have gone in there and have actually used the tools in Trimble Stratus to lay out roads and then kick the designs back out into CAD or to the survey guys to physically go stake out those roads in the field,” Paul explained. “So they’re essentially reverse engineering from Propeller back to the field, which is awesome. And I tell those guys, always let me know about these new uses so I can share with the other project managers. It just makes the tool more useful for everyone.”

Paul added that the platform has also been helpful in spotting errors in original design drawings, which, if not caught, can lead to costly rework. For one job, he flew the site before work began and provided the data to the project manager, who told him she thought his data was off because there was a discrepancy between the engineer’s topographical map and the survey data.

“So, I went back out there, flew the site a second time,” Paul explained. “I got the second data set back, ran contours on the first data set and the second, and they were perfectly on top of each other like they should be. I asked the PM to show me the area where she was seeing the discrepancy, and she circled it on the map. From my Trimble Stratus data, I was able to point out a 20-foot deep creek bed that was missing from the engineer’s topo. So, we were able to push that back and get the plans revised without us having to eat the cost and fix it ourselves because we caught it early enough with our data.”

An accurate, affordable project management tool

For those considering a drone survey program for their excavation business, Paul stresses that the cost is well worth it.

With our use of Trimble Stratus, we’ve proven time and time again, it can pay for itself by catching just one topo map error. The accuracy of the program blows me away constantly, and the drone data is as accurate as the survey data that it’s based on, in my opinion. It’s well worth the investment.

Want to know how Propeller can help you?

Learn more about Propeller’s products, pricing, and how to get started on your site.