Anyone who works in the mining industry will tell you that projects are anything but straightforward. Planning, extraction, and reclamation are all a tangled web of interwoven timelines, and lifespans that are tricky to predict.

Aerial drone surveys are valuable in every stage of the process, from planning all the way through reclamation.

What is reclamation in mining?

Mine reclamation is the process of restoring mined land to pre-extraction conditions. When you reclaim land, you’re minimizing the adverse impact of mining on the surrounding ecosystem. The most common approaches to reclamation are reforestation and new development.

Remediation plans are not an afterthought, but rather part of the initial mine planning process with budget allocated before work begins on a site. Regulatory bodies like OSMRE (the Office of Surface Mining Reclamation and Enforcement) in the US want insurance that you’ll eventually be able to decommission and repurpose the land—before you break ground.

No matter what your reclamation plan, it involves a massive effort, requiring careful tracking of material movement and coordination of effort between multiple stakeholders, including regulatory oversight. So how do you know whether you’re tracking toward that plan, and how long the process will take?

Historically, it was hard to tell. But drones are changing that.

Firm up timelines and evaluate lifespan

Mining contains its fair share of uncertainty. At the start of a project, there’s no way to know precisely how long a mine will remain active or how much extractable material lies beneath the surface. The volume of material to be moved (ore and waste) is also continually updated as the extent of the resource continues to be defined.

The best way to reliably predict how much work remains— and when reclamation will begin—is by tracking progress and material movement often during extraction. Aerial surveys conducted via frequent drone flights are the best way to collect this data quickly and accurately.

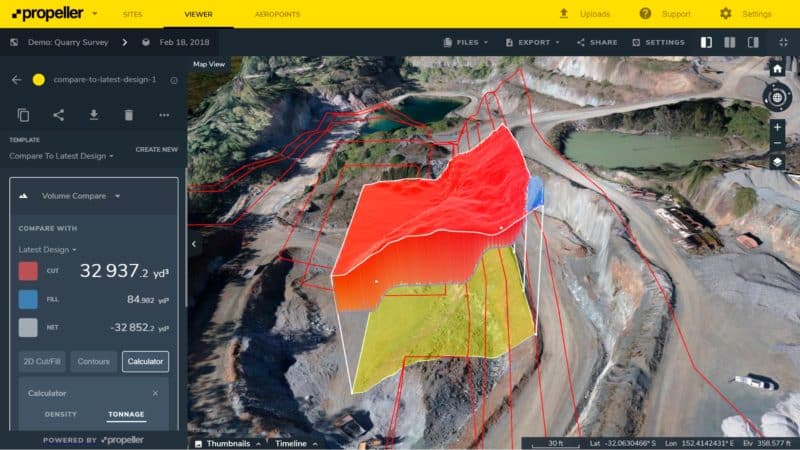

With a 3D model of your worksite, you can layer datasets to compare material movement between flyovers. You can also analyze the current conditions against historical data to monitor progress, and use cut/fill calculations to estimate how much ore/waste remains. 3D maps rendered from drone data also provides insight into tailings volumes and waste rock.

For example, Cara Rosen, a technical services lead with Orica, told us that she reviews her team’s progress with Propeller every month. Using the Propeller Platform, she examines where crestlines are falling for blast progress and the volume of material moved.

Accurately calculating how much material you’ve removed sheds light on an otherwise difficult to predict reclamation timeline. With an accurate drone survey, you can estimate the amount of backfill needed to restore the grade, identify problem areas that will require more attention, and flag safety hazards that might impact reclamation.

Design better blasting plans

Mining is intimately tied to reclamation. The more accurately you estimate the volume of extractable material, the more strategic you can make your blasting plans.

Propeller PPK makes it easy to create blasting plans based on 3D site models, including rock type variation in a bench, face angle, pre-blast rock condition, and blast volumes.

Detailed orthos can also be used to overlay drill and blast designs and determine whether the drill pattern should be adjusted. You can even identify volumes to blast on the 3D model with point-and-click functionality—simply draw a polygon around the proposed blast area, set the bench level, and get automatic volume calculations.

Once blasting is complete, you can re-fly a site to get post-blast analysis data in just a few hours. Use Propeller’s volume compare-to-design tool on the blasted volume to confirm whether the correct amount of material was extracted.

Having data at your fingertips adds an increased level of certainty to your workflow. Blasting plans created on a foundation of historical extraction data are more accurate, and therefore will minimize environmental impact and make site reclamation easier.

Fast, frequent surveys make economic sense, too. Nevada Gold Mines uses Propeller to conduct daily stockpile surveys for a fraction of the cost and in far less time than traditional land-based methods.

Keep everyone in the loop

Keeping necessary stakeholders informed is its own challenge, especially in the complex regulatory environment of mine reclamation. Returning mined land to a usable state requires involvement from many different people: clients, government agencies, developers, contractors, and your team on the ground.

What’s more, there are competing incentives for those involved . Regulatory agencies are tasked with protecting the environment, site managers need to ensure profitability, and everyone wants to work efficiently and safely.

Getting the right information to the right people is easy with drone data, in part because drones are unbiased observers. There’s nothing anecdotal about an image-based 3D map, and no guesswork in a survey accurate to 1/10 foot. The Propeller Platform serves as a single, objective source of truth that all stakeholders can reference, ensuring that everyone is speaking the same language.

Once your drone data syncs to the Platform, you can share progress and reporting with anyone who needs to see it. Team members on the ground can leverage the data to plan future blasting and monitor haul roads while managers monitor progress from the office.

If your mine will be repurposed during reclamation, you can share survey data with contractors who will initiate a new build on the land once you’ve left. They can track land degradation as you extract, creating a well-informed earthwork approach based on real-time data.

And, for those times when a dispute is unavoidable, Propeller offers a complete record of progress to resolve disputes as quickly and painlessly as possible.

Conclusion

A well-established drone surveying workflow is the best way to reduce ambiguity, create accurate plans, and streamline communication during every stage of a mine’s lifecycle. Drones capture everything happening on the ground without the subjectivity of the human eye—not to mention without endangering your team.

While it may not be possible to predict the lifespan of your mine to the day, you can proactively monitor your site health during planning and extraction, and eliminate some of the reactivity that can to occur during reclamation.