Now that we’re expanding Propeller’s PPK solution with additional drone hardware, we’re getting more questions than ever about how PPK works, and what sets it apart from RTK drone surveying.

We firmly believe that PPK is the best solution for almost any worksite, no matter what industry you’re in, so we thought we’d take the time to explain why.

For a more in-depth explanation, or to learn how ground control and AeroPoints factor into your drone surveying workflow, check out our recent post How It Works: PPK vs RTK Drone Surveying.

You’re probably wondering why a workflow that uses an RTK-enabled drone is called “PPK.” This is a common point of confusion, because RTK and PPK are like apples and oranges—we’re not really talking about the same thing.

What is RTK?

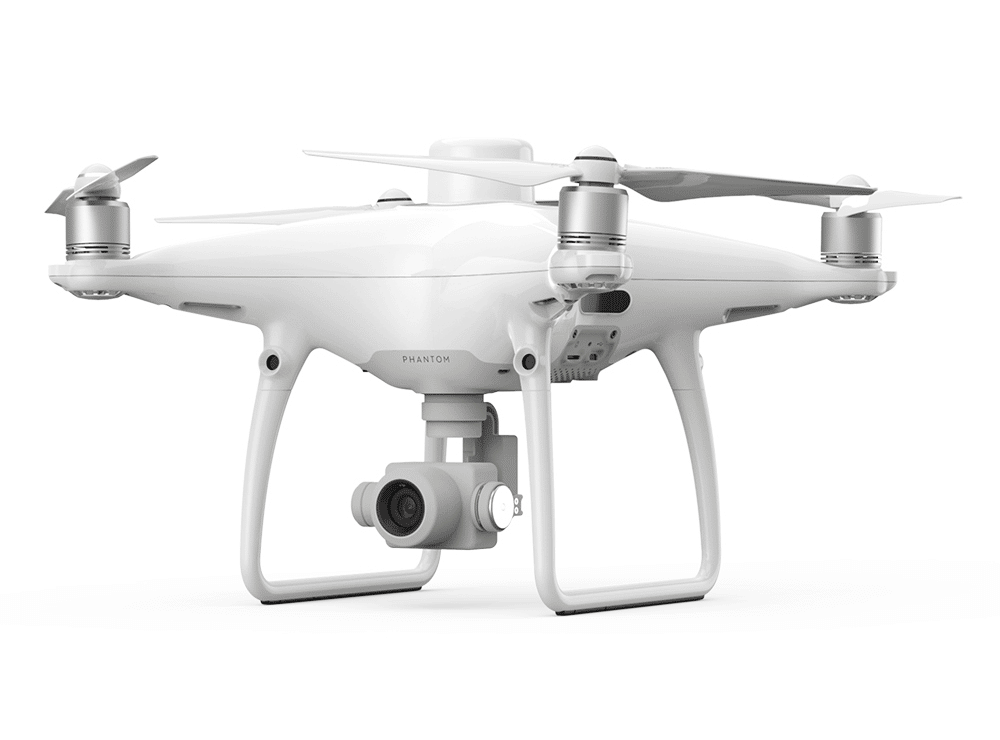

RTK stands for real-time kinematic. It describes onboard drone hardware that allows a survey drone to communicate with a base station in real time to validate its location in space. This ensures survey-grade accuracy in the collected photogrammetry data.

PPK, by contrast, isn’t hardware at all. It’s an entirely different processing workflow using RTK data.

What RTK technology is and how it works

Real-time kinematic (RTK) processing on a drone records GPS information and geotags images as they’re captured during flight. The GPS location is recorded for the center of each image.

An active base station on the ground sends raw GPS data to the drone. The drone’s onboard GPS unit then combines that info with its own observations to accurately determine its position relative to the base.

To achieve the desired accuracy, an RTK drone must stay connected to the base station while it’s gathering data.

Unfortunately, signal loss during flight is fairly common—and when it happens, the data is unreliable until the drone regains contact with the base station. This can happen during turns due to antenna orientation, while flying behind trees or buildings, or for other reasons that are difficult to avoid.

What PPK drone surveying is and how PPK works

Propeller’s PPK workflow uses RTK drone hardware to collect the survey data; however, the actual processing of that data occurs after your drone flight is complete. That’s why PPK stands for “post-processing kinematic.”

In a PPK workflow, the drone attaches geocoordinates to each image based on an onboard GPS. Also during flight, a base unit (which could be a base station, an AeroPoint, or CORS network) also records positional information, but with more accurate triangulation.

Post-flight, the two sets of GPS data are matched using timestamps on the photos. The more accurate positional data from the base is used to course-correct the data collected by the drone.

Although “real-time” technologies are appropriate in some situations, post-processing photogrammetry data makes drone surveying faster, simpler, and more reliable than ever before.

Want to dig into the details?

We’ve got you covered. Check out our PPK digital guide to cut through the confusion and get straight to what you need to know about PPK.