How Collins Earthworks opened up site data to the whole team with Propeller

For Adam Procter and his team at Collins Earthworks, progress used to be gated by a single point of access. “Our data was stuck,” said Adam, Technical Director at Collins. “We were collecting it, but sharing it was difficult. Only one person could do the processing, and getting that information to the wider team was a real challenge.” But that was before Collins brought Propeller into the fold. Today, Propeller’s platform is the central hub for drone-captured data across Collins’ operations. From commercial and estimating to site operations, teams across the business now have direct access to rich, visual, and measurable site data without needing to go through Adam or anyone else first.

A scalable way to scale bulk earthworks

Collins Earthworks specializes in, you guessed it, earthworks. With major UK infrastructure projects on their roster (including highway schemes, HS2, and freight interchanges), they’re no strangers to massive sites, tight timelines, and multi-stakeholder coordination.

Their toolkit is as robust as their scope: total stations, GNSS rovers, drone surveys, and machine control. But as Adam puts it, drone data used to be more trouble than it was worth.

“We tried different drones and different workflows. We eventually landed on the DJI Matrice M300 Enterprise, which does a brilliant job, but the real breakthrough was Propeller,” he said. “It’s made drone data handling more simplistic. And more importantly, shareable.”

Self-service measurements = faster decisions

Before Propeller, teams were often waiting on survey results or pulling engineers away from high-priority tasks to get progress updates. Now, with Propeller, that bottleneck’s gone. The commercial team can now carry out their own volumetrics independently.

The estimating team is layering design surfaces over current site maps to build smarter bids.

Site managers are measuring stockpiles, reviewing plans, and adjusting workflows all in the field. In total, more than 100 users across the Collins group are actively using Propeller today.

“It’s changed how we work. Everyone can get what they need, when they need it,” Adam said. “And it’s saving our engineers a ton of time.”

Northampton Gateway: A big test, a bigger win

One of Collins’ most prestigious projects (the Northampton Gateway Strategic Rail Freight Interchange) spans over 200 hectares and has been running for more than five years. It also served as a proving ground for Propeller’s capabilities.

Adam recalls that early drone flights on the project were being processed the old way: one machine, one seat, one person. Once Propeller was brought in, things shifted quickly.

“From 2023 onwards, we started uploading through Propeller and never looked back,” said Adam. “We could share the visuals and measurements across the whole team. We were using that data to track progress, verify quantities, even resolve disputes.”

The Propeller tools that power Collins' projects

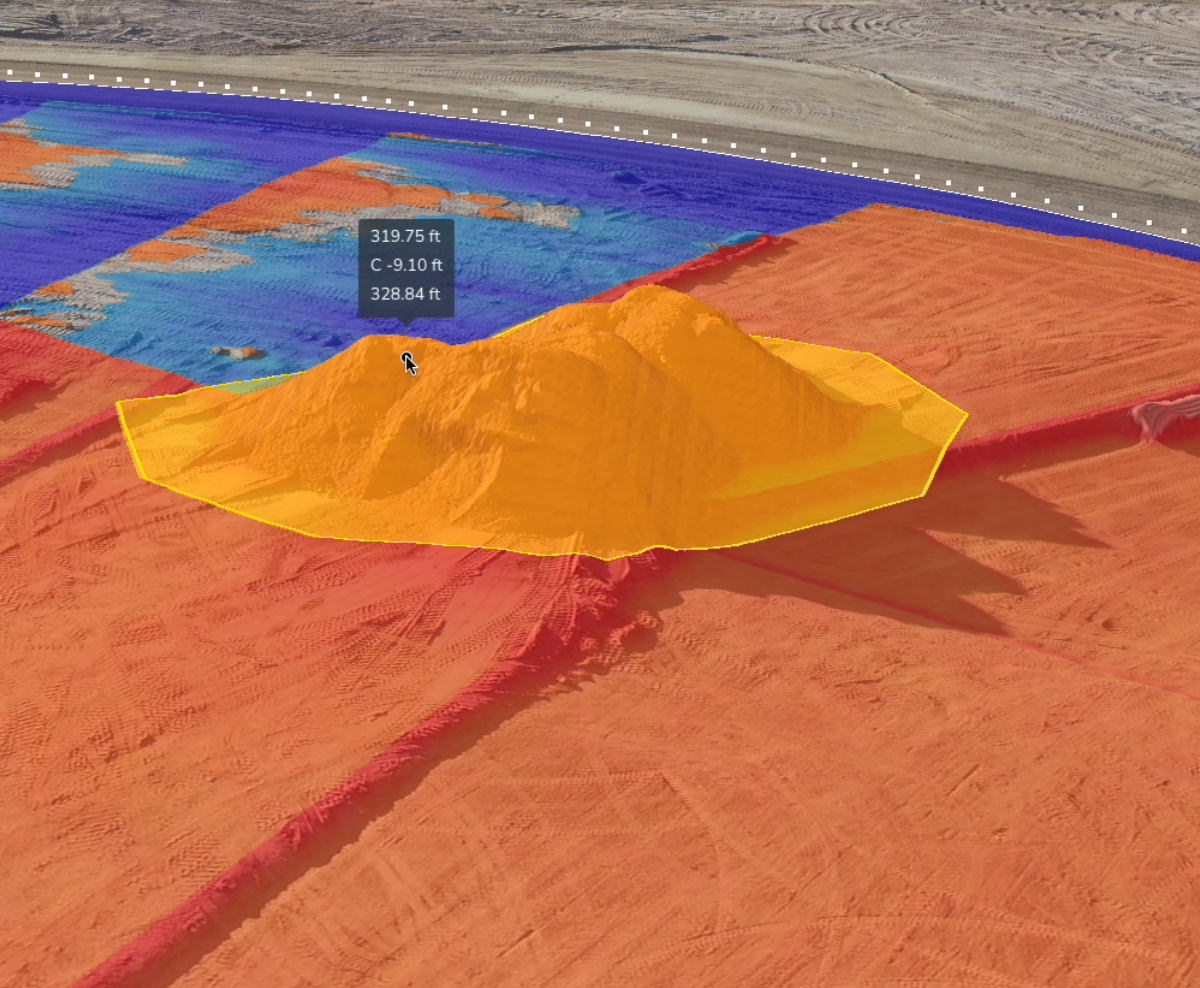

1. Magic polygon

Problem it solves: Waiting on engineers or traditional surveys to calculate volumes

What it does: Lets users quickly outline stockpiles or irregular areas to calculate volumes without needing CAD files or perfect drone coverage

How Collins uses it: Quantity surveyors use Magic Polygon to do their own progress measurements for monthly valuations. It’s cut down reliance on engineering teams and sped up commercial workflows.

2. Vertical face imagery

Problem it solves: Lack of visual documentation for steep terrain or removed equipment

What it does: Generates photo-aligned vertical surfaces for inspection and documentation

How Collins uses it: Helps visualize cleared areas and confirm what’s been removed from site. Especially useful for tracking equipment or infrastructure during phases of construction or demolition.

3. Timeline view + Survey overlays

Problem it solves: Hard to track how a site has changed over time

What it does: Allows teams to view multiple surveys over time and compare against designs

How Collins uses it: On long-term projects like Northampton Gateway, it helps teams calculate progress, understand sequencing, and verify changes. In turn, this leads to resolving disputes and validating progress claims.

4. Linework + Design surface overlay

Problem it solves: Difficult to validate design intent or visualize future works

What it does: Overlays CAD linework and design surfaces directly on drone maps

How Collins uses it: Estimators overlay designs on real site conditions to plan works, identify risks, and present bids with clear visual context. It’s also used for programming construction phases on active sites.

5. Markup + Annotations + Draw tools

Problem it solves: Communication breakdowns between office and field

What it does: Enables teams to add comments, notes, lines, and shapes directly on the map

How Collins uses it: Site managers and supervisors use annotations to communicate plans and progress clearly without needing engineers to interpret or package data.

6. User permissions + Sharing settings

Problem it solves: Sensitive data exposure or platform clutter for large teams

What it does: Lets admins set exactly who can see, measure, or upload data

How Collins uses it: With more than 100 users, Collins uses permissions to ensure every department has what they need.

7. Mobile App (Propeller Platform on Mobile)

Problem it solves: Field teams struggling to orient themselves without up-to-date context

What it does: Brings full site access to mobile devices for real-time reference in the field

How Collins uses it: Site managers use the app to orient themselves and plan without having to rely on machine-controlled plant or site engineers.

8. Export tools + Platform interoperability

Problem it solves: Siloed workflows between Propeller and other tools

What it does: Exports data layers, annotations, and visuals for use in CAD, SketchUp, and other platforms

How Collins uses it: Collins shares annotated designs and visuals for reporting, bid packages, or client presentations without needing to rework files or rely on engineering time.

Data they can trust and prove

With Propeller, Collins now has a visual record of every survey, which is something they’ve already used to prove when and where ground movement happened, and to settle commercial disputes.

The platform has also become a powerful presentation tool for their clients.

But Adam says the biggest benefit is still the simplest: “People don’t have to wait on others anymore. They can measure it themselves. This negates the need to appoint a site engineer, as well as the office team to then process, volumise and report the quantities back.”

Final word from Adam

“There are plenty of drone platforms out there,” Adam said. “But what makes Propeller stand out is the responsiveness. If I have a feature request, I know it’ll be considered. The help videos, the global support, the platform… it’s all smooth, consistent, and easy to use.”

Want to know how Propeller can help you?

Learn more about Propeller’s products, pricing, and how to get started on your site.