The term “risk” typically conjures up images of safety concerns, like falls or being struck by equipment, particularly on a construction site. But these are not the only risks that earthworks professionals keep on their radar. Other risks may be related to budget, timelines, staffing, or efficiency, to name a few.

By leveraging advanced technology solutions, like drone hardware and drone data analytics software, earthworks contractors can confidently save time, reduce spend, and boost efficiency. In fact, many contractors are surveying their site more often with the use of drones to mitigate these risks.

Accuracy meets efficiency

The “old” way of surveying worksites and collecting data by physically walking a site is not only labor- and time-intensive, it’s simply not safe or advisable—especially when there’s a better way to achieve the same result faster, safer, and with greater efficiency.

Consider this: with a base and rover, by the time you’ve finished surveying a large worksite, it already looks different than it did when you started. It can start to feel like an expensive hamster wheel, always chasing after accurate survey data, but never quite achieving it. Unfortunately, this means that contractors need to make do with weeks-old survey data.

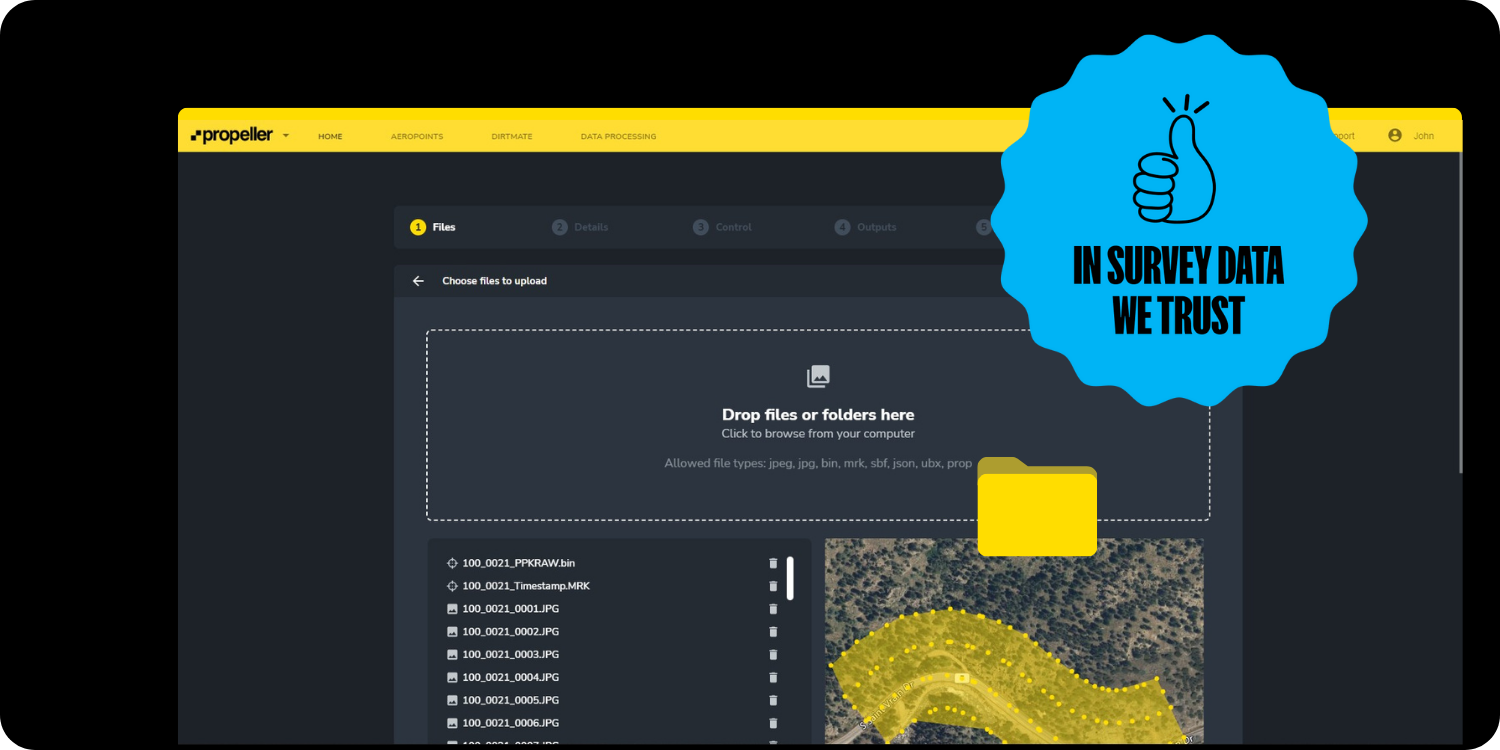

Today, many contractors are finding value in drone surveying to reduce time spent in the field collecting data, and more time making smarter, faster data-driven decisions that positively affect their business.

Drones are easy to operate, which means several team members can be trained to fly, reducing the risk of a single point of failure in drone operation. Essentially, by cross-training team members on the use of drones on your site, you’ll never need to worry if the one person who is trained to fly suddenly comes down with the flu or otherwise can’t make it to work.

Plus, you don’t even need to use traditional ground control. Very often, it’s just a matter of placing a smart ground control point nearby and hitting “Go” on a pre-programmed flight path. The site survey can be flown in as little as ten minutes, and highly accurate survey data can be accessed in 24 hours. That data can then be used to identify areas of risk, improve efficiencies, track progress, and so much more.

Justin Russell, head surveyor at Fiore & Sons, more than tripled his daily survey output when he switched from traditional surveying to a drone program. With that kind of efficiency, frequent surveys are both simple and effective.

And there’s no need to sacrifice accuracy. Propeller PPK yields data accurate to 1/10 foot—equal to traditional methods, but in a fraction of the time.

Speak the same language

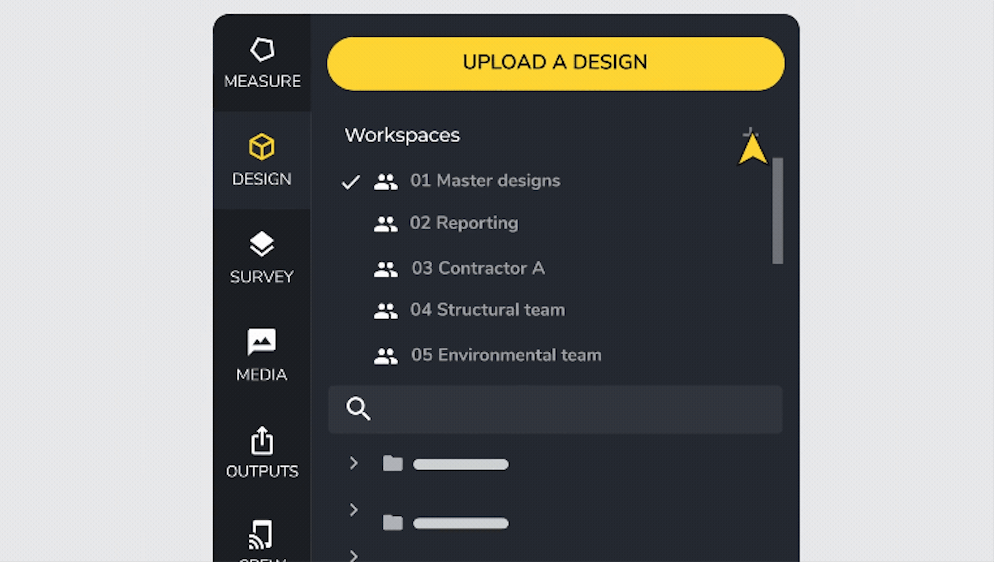

Traditionally, with multiple contractors working on a project at the same time, collaboration has been a challenge. Multiple sets of design drawings, different (sometimes overlapping) areas of work, and competing priorities make it difficult to ensure that everyone is looking at the same picture of the site’s status and progress.

When everyone shares a single source of truth for what’s happening on a job site, things run a lot smoother.

3D maps created from drone photogrammetry can provide a nearly real-time comparison against design. With just a few clicks, anyone on a project can get precise measurements for cut/fill, material volumes, surface slope, and other key measurements.

In other words, everyone knows exactly what’s happening on a site and when, so work can be coordinated and managed with ease. Additionally, mobile apps like Propeller’s add-on module Crew keep everyone in sync, whether they’re in the office or in the field.

Avoid overrun and finish on time

Cost overrun is a real problem in construction. Nine out of every ten projects experience overrun, with an average overage of 28%.

Drone surveying software like the Propeller Platform makes it easy to track a site’s current state against design and plan, flagging potential pitfalls before they can derail your timeline or your budget.

Knowing where your materials and machines are in real time means that you can keep the right people in the right places at the right times, avoiding costly mistakes and optimizing labor.